The process of using a highly focused beam of light to engrave 3D forms into metals has been around for centuries. Some tools that can do this are called pulsed fiber lasers, and they’re the best choice if you want your designs deep enough so they will be pleasurable both visually and when touched upon by hand!

Role of Laser

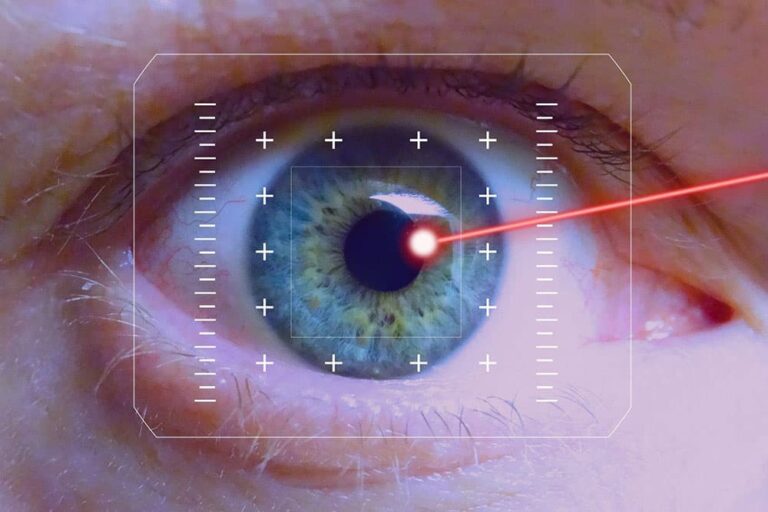

Lasers are playing an ever-expanding role in material processing, from new product development to high volume manufacturing. For all laser engraving processes, the energy of a single beam interacts with materials and transforms it via light reactions that can be precisely controlled by regulating factors like wavelength or power consumption rate at any given time.

Changing everything about how these beams interact including what changes occur when they do! This gives us access not just to specific tasks but also limitless possibilities as technology progresses day after day.

Which Machines Do You Need for Laser Engraving?

It’s a long process that may take several minutes or even hours to engrave a single part. Deep laser marking machines are better because they don’t require automation, making them more affordable in comparison with other types of machines and enabling you just need to load new parts when yours was done.

Deep lasers can be enclosed within manually operated ones since it’s an extended procedure consisting mainly of coming back for another component after completing one spot on each item Check our website they also provide higher quality than alternatives such as speed writing systems which work well but come out less precise.

How Does the Laser Engraving Work?

The laser beam is like a sniper’s bullet. It has to be aimed at its target, fired with precision and timing in order for the shot to payoff! Within 1 second, 100W can release 100000ths (ten thousandths) pulse contains 1 millijoule heat which converts into peak power reaching 10 kilowatts for each time it hits material’s surface while reflecting most back but some also absorbed by converting them to heat instead!

The different patterns on the surface cause color changes to appear, and high-quality markings like black and white offer the best contrasts for this effect. However, each application requires a slightly different process since it’s optimized specifically with your needs in mind; if you want an answer about how etching works then ask someone who knows!

Laser Cutting of Metal

The Fiber laser beam melts through most metals, leaving smooth and straight edges that are free of the heat-affected zone (HAZ). Bubbles form as the material absorbs its energy. A jet of high-pressure air is used to remove this molten pooling metal before it can solidify in order for us to maintain quality control on our product!

Laser Engraving of Metal

The power of the Fiber laser beam is limited so that it can remove material to a specified depth. This process may require multiple passes and the common allowance for metal engraving is 0-0.003″.

But if too much metal were removed in just one pass, then melting or distortion would occur which makes two holes instead of one big enough for identification purposes only – not removable without heat/wearable accessories such as rings!

Effect of Laser Engraving on a Steel

You’ll need to be very cautious when engraving stainless steel because you will remove the protective oxide layer that prevents it from rusting. To get a clean surface finish and avoid any color changes during the process (which generally result from laser parameters).

You should set your machine’s settings in such a way as not too quickly or else blacken its color, but if there isn’t enough time for this then expect some other unwanted outcome like spotting metal particles all over your piece instead of getting smooth cuts with nice edges like desired!

Safety Precautions

Laser printers and laser cutters are responsible for manufacturing some of today’s most intricate parts. For this reason, it is important to know the safety precautions involved in using these machines as well as which type or types of enclosure will best protect your employees from potential hazards associated with them.

These infections are by germs carrying contagious diseases like tuberculosis (TB), hepatitis B virus; skin burns; eye damage due to an accident at work). The Class-1 Laser Safety Enclosure meets international standards and keeps workers free from harmful rays generated when vaporizing surface material during deep engraving processes used on projects created here.

0 Comments