Selecting the right laser micromachining service requires a strategic approach, balancing expertise, technology, and reliability. Laser micromachining, a precision-driven process, demands a partner with cutting-edge tools and extensive experience. In pursuing excellence, one must consider key factors: the company’s proficiency in handling intricate projects, technological capabilities, and track record with diverse materials.

Equally important are client testimonials and industry reputation, offering valuable insights into reliability and service quality. Balancing cost-effectiveness with high-quality output is pivotal; thus, a comprehensive evaluation of capabilities against pricing structures becomes essential.

In this competitive landscape, the quest for the best laser micromachining company demands meticulous research, thorough assessments, and a keen eye for a partner who can meet and exceed specific project requirements.

Below, we discuss how to choose the best laser micromachining company.

Expertise and Technology

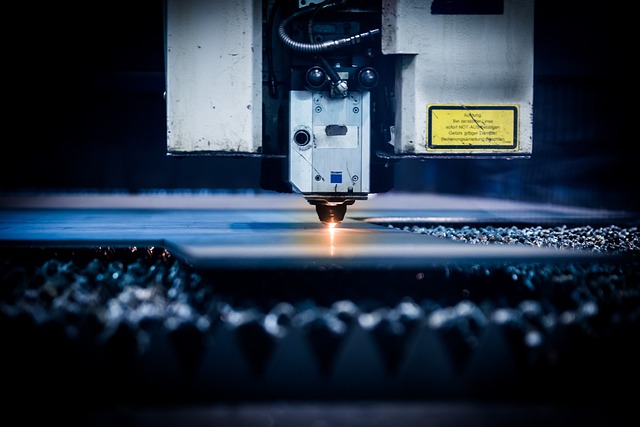

Look for companies with a strong track record of expertise in laser micromachining. Check their technological capabilities – from the types of lasers they use to their precision tools. A top-notch company will often have various laser systems like femtosecond, picosecond, or nanosecond lasers, and they’ll stay updated with the latest advancements in laser technology.

Additionally, inquire about their experience handling materials similar to what you need to be machined. A firm understanding of materials is crucial for successful micromachining projects.

Quality Assurance and Precision

The best laser micromachining companies prioritize quality assurance. They should have stringent quality control processes, ensuring each piece meets specifications. Ask about their quality assurance protocols, inspection methods, and if they adhere to industry standards and certifications.

Look for case studies or testimonials that showcase their precision and ability to deliver high-quality results consistently.

Customization and Flexibility

Opt for a company that offers customization and flexibility in their services. Not all micromachining projects are the same, so a company that can adapt to unique requirements, whether in design, materials, or project scale, is invaluable.

Ask about their ability to tailor solutions to your specific needs. A company that values customization often delivers more precise and efficient results.

Project Management and Communication

Smooth project management and clear communication are vital in any machining process. The ideal company will have a robust project management system to ensure timelines are met and the project progresses seamlessly.

Additionally, they should maintain open communication channels, providing regular updates and being readily available to address any concerns or queries. Assess their responsiveness and willingness to communicate clearly from the initial stages.

Cost and Lead Times

While cost should not be the sole determining factor, it’s essential to consider it. Request detailed quotes from different companies and compare the pricing and value offered for that cost.

Evaluate lead times – a reliable company will provide realistic timelines without compromising quality. Beware of unusually low prices, as they might indicate compromises in quality or service.

Final Thoughts

Choosing the best laser micromachining company hinges on expertise, precision, adaptability, effective communication, and a balance between cost and quality, ensuring tailored solutions for optimal project outcomes.

0 Comments